Company History

From its inception in a one car garage in the 1970s to its present 50,000+ square feet of manufacturing and office area, The Sollami Company has evolved from a single purpose supplier to a multipurpose manufacturer of innovative products encompassing several industries’ needs.

The Sollami Company began by developing a machine for the mining industry, which changed a hand-held grinding operation of used carbide bits into a much more productive semi-automatic operation. This patented specialized grinding machine quickly changed the older, more labor-intensive method, and became an industry standard.

With the universal acceptance of their original roof bit grinding machine, The Sollami Company began expanding their product line focusing on the coal mining industry. As challenges presented themselves within the industry, corrective action was needed to resolve them. One problem which surfaced was the rotary actuator supplied to The Sollami Company’s operation. The supplier was unable to resolve problems which led to a short actuator life. In an effort to improve the operating life of the rotary actuator, The Sollami Company boldly undertook a course of action to develop an actuator on their own which would withstand the force and punishment that would be necessary for their grinding machine application. After extensive research and development, they succeeded.

By 1996, the Sollami Company completed a project for Johnson Engineering Corporation, an engineering development facility for NASA. Engineers at Johnson Engineering Corporation recognized Sollami Company had a patented vane-type rotary actuator and concluded it would be a useful component for a Remote Manipulator System (WRMS) at their Weightless Environment Training Facility (WETF) located at Johnson Space Center. The WRMS (an under-water training device on Earth) was certified by NASA for astronaut training on Earth to simulate the use of a similar device used in outer space on their missions.

The Sollami Company’s engineering and manufacturing facility had the latest, technologically advanced equipment to support its efforts. CAD-CAM (computer-aided design – computer-aided machining) software and computers assist in the preparation of critical designs and prepare transfer of data to computer operated lathes and vertical machining centers. This equipment makes it easy to correct flaws in the early stages of development.

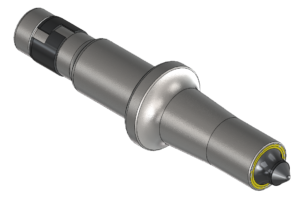

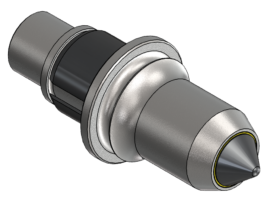

The Sollami Company expanded their product line to serve other industries. By using similar concepts of products used in the mining industry, Sollami offered new products that were created and developed for use in the trenching construction and highway construction (milling) industries. The Sollami Company now manufactures brazed carbide-tipped tools and accessories for the mining, road milling, foundational drilling, and trenching construction industries. This includes the innovative Quick Change Tool System for the milling industry. All designs, research and development, marketing, and sales are completed in-house, and manufactured in the USA.

The Sollami Company currently holds 60+ patents.

An American Veteran, Family Owned & Operated Company for over 48 Years!